Thriving amid a global pandemic takes hard work, commitment, thinking outside the box, and having marketing options in place. That’s according to Gary and Parker Yost, who have a cattle feeding operation in Wheaton, Minnesota.

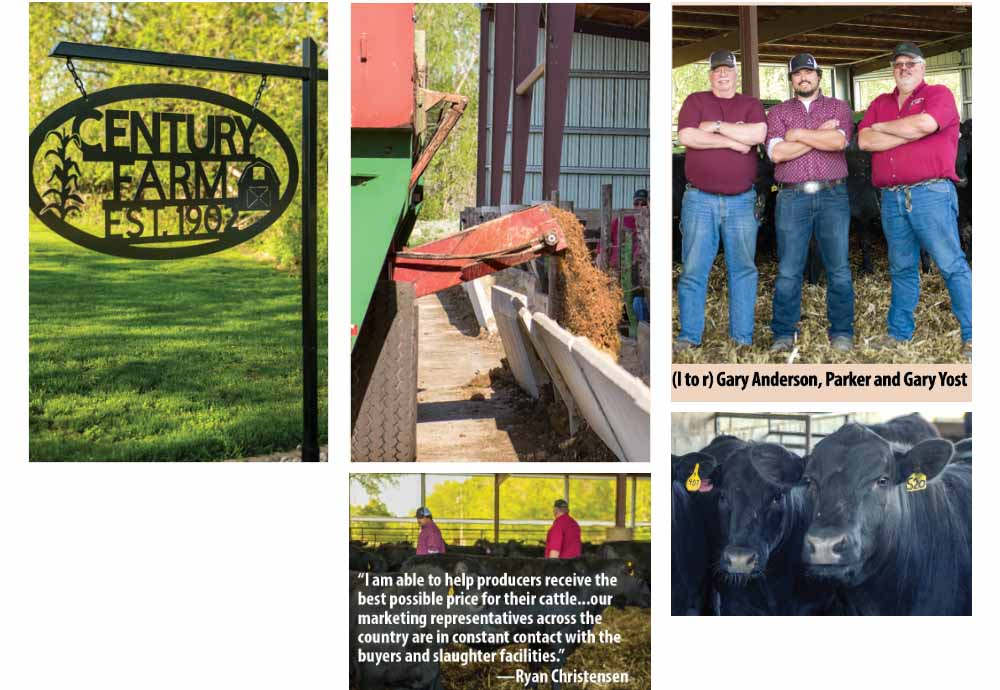

The Yosts operate a 600 head finishing operation on land that has been in Gary’s wife’s family since 1902. It’s no easy feat running a sustainable livestock operation in today’s world, and the Yosts plan on keeping this land in the family for at least the next 120 years.

While many livestock operations have faded from Traverse County and the surrounding area, growing their cattle business has been their top priority.

“I began farming with my father-in-law, Gary Anderson, in 1993,” Gary Yost said.

The cropland raised corn, soybeans, and hay, while the pasture supported a cow-calf operation.

“We backgrounded our calves then expanded, feeding 200 calves in open lots. In 2010, we got out of the cow-calf business and concentrated on finishing cattle,” Yost explained.

When Parker returned from college in 2018, they expanded again.

“Planting corn, watching it grow in the same ground your ancestors have walked, seeing calves come in, happily eating and content, growing to finish weight—there is not any better feeling,” Parker Yost said. “I have never imagined myself doing anything else.”

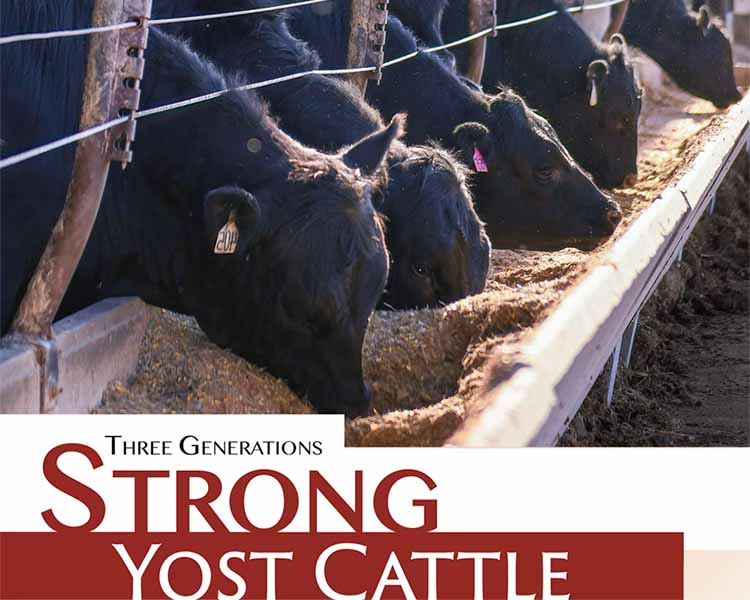

Feeding Operation Moved Inside

To accommodate feeding more cattle on the same land, the Yosts were faced with a total revamp of the existing outside lots, or they needed to figure out what type of indoor facility would work.

“We toured several buildings and decided a monoslope barn would meet our needs,” Parker Yost noted.

“The barn has enabled us to finish 600 head and checks all the boxes related to cattle health and their management. The barn also contributes to environmentally sound management practices that enable us to increase soil health.”

The barn is 90×360 with three pens. Corn stalks are used for bedding and there is a 65×360 manure bay. The barn takes the weather, winter snow, and summer heat out of the feeding equation so that the cattle gain uniformly throughout the year.

“In the summer, there is a nice breeze and 90 percent shade inside the barn. In the winter, with the sun lower in the sky, the barn is filled with 90 percent sun,” Parker Yost said.

The Yosts believe in low-stress stock management and the cattle benefit from that mindset. The barn is set up so everything flows well and the cattle naturally move from one area to the next due to plenty of light, well-placed gates and alleys, and no corners. A tub leads to a double working alley, and a bud box is used for loading out cattle. Bedding the barn takes place once a week when the calves have access to outside lots.

“It’s kind of like recess. They run and buck outside but are just as happy to come back in where fresh bedding awaits when recess is over,” Parker noted.

Western calves are purchased through Superior auctions at 500 to 600 pounds and shipped to the Yosts in the fall. The calves are given about a month to settle in before they are worked.

“Many of the western calves aren’t used to seeing people, but they acclimate quickly,” said Parker Yost.

Stress tubs and minerals are provided in addition to feeding a total mixed ration (TMR) twice a day.

“The TMR is made mostly of feedstuffs grown on the farm. Calves are fed 25 percent to 30 percent high moisture corn, silage, modified distillers grain, ground grass hay, alfalfa, and straw,” said Yost.

Vaccinations begin about four weeks after arrival, along with an implant and pour on.

“We can work about 120 calves an hour. It’s low stress for them and us,” said Yost.

Blessed and proud to be working side by side, the three generations of men share daily chores.

Environmentally Sound Practices

The Yosts attempt to do things as naturally as possible and use environmentally sound practices. To ensure their cattle’s nutritional needs are met, they work closely with a nutritionist and veterinarian. “For fly control, fly parasites are shipped from BioSwat in Boulder, Colorado, and added monthly to the stockpiled manure, reducing the mature fly population,” Parker Yost said. “We have zero runoff with the barn, not the case with our old open lots.”

The manure from the barn is spread onto the crop fields in the fall. Consulting with a crop advisor, the Yosts ensure their fields benefit from the cattle manure and bedding without negatively impacting the environment. Soil tests and manure nutrient content results are aligned so that the fields acquire the needed nutrients without overfertilizing.

“We chisel plow the manure into the soil within 12 hours of spreading, capturing the maximum nitrogen amount available while keeping the smell and potential runoff to a minimum,” said Parker Yost.

The wildlife provides unique challenges for the Yosts. They can have 250 deer at their winter feedlot, in addition to turkey, pheasant, and even eagles. To keep the deer from eating the cattle feed, the Yosts use freestanding panels and make a fence with hay bales stacked two high around the silage and high moisture corn pile.

“The wildlife is neat to see, but they add challenges to winter feeding,” Parker Yost said.

National Farmers Provides Marketing Options, Peace of Mind

The cattle are shipped to slaughter at 1,200 to 1,400 pounds.

“We used to rely on local sale barns within 70 miles of the farm, but that limited our marketing options,” said Parker Yost. “Once we began feeding more calves, we became National Farmers members on the advice of a neighbor. While we utilize a local butcher and sell some freezer beef to family and neighbors, most of the cattle are sold directly to a packer.”

“National Farmers and our marketing representative, Ryan Christensen, are well connected and give us multiple marketing options that we wouldn’t have without them,” Gary Yost said.

“I am able to help producers receive the best possible price for their cattle,” Christensen said. “The greatest benefit for producers working with the National Farmers Organization is that our marketing representatives across the country are in constant contact with the buyers and slaughter facilities.”

Being in the market on a daily basis rather than once or a few times in a year like most producers enables National Farmers representatives to know what the plants are looking for and understand what type of cattle they don’t need. Then, it is just a matter of matching the cattle with the right plant, explains Christensen. “Our network enables us to facilitate matches across the country, expanding marketing options for our producers.”

National Farmers also offer assistance with trucking, sorting, and if needed, lining up loads for smaller producers to add their cattle with others, capturing a better premium. However, the Yosts are great stockmen and have an excellent facility, so they handle all of that themselves, remarked Christensen.

“Of course, the better-quality cattle that yield and grade well always bring a premium and are easier to market,” said Christensen about the black-hided western cattle the Yost’s feed.

“We were fortunate to be affiliated with National Farmers during the pandemic. As the pandemic progressed, lots of plants were shutting down. It gets very costly trying to maintain a fat animal; when they are ready to go, they need to be shipped. Because of Ryan’s connections, we were able to market our cattle further afield, in seven different states, and didn’t have to deal with supply chain issues or slaughter plant closings,” Gary Yost noted.

“Even two cents higher on 600 calves adds up quickly. We know three weeks in advance when we are shipping cattle and where they are going. That gives us peace of mind,” concluded Yost.